|

ระดับ |

ความหนาแน่น |

คุณสมบัติทางกล |

โมดูลัสยืดหยุ่น |

อัตราส่วนของปัวซอง |

การนำความร้อน |

ใช้/ทดสอบอุณหภูมิ |

คุณสมบัติและการใช้งาน |

|||

|

ความแข็ง |

แรงดึง |

ความแข็งแรงของผลผลิต |

การยืดตัวหลังขาด |

|||||||

|

ρ/g•cm-3 |

HV |

Rm/MPa |

Rp0.2/MPa |

เป็/% |

เกรดเฉลี่ย |

— |

พร้อมmk |

℃ |

||

|

LZ91 |

1.48 |

40-75 |

140-180 |

110-130 |

15-40 |

43 |

0.33 |

เกี่ยวกับ50-80 |

≤100 ℃ |

ความหนาแน่นต่ำ ความแข็งแรงปานกลาง รูปร่างดี ความต้านทานการกัดกร่อนที่ดี เหมาะสำหรับชิ้นส่วนเปลือกของการบินและอวกาศ อิเล็กทรอนิกส์ 3C และผลิตภัณฑ์อื่น ๆ แอพลิเคชันตลาดที่ใหญ่ที่สุด |

|

LAZ931 |

1.51 |

50-75 |

170-220 |

140-180 |

10-20 |

43 |

0.33 |

เกี่ยวกับ50-80 |

≤100 ℃ |

สมบัติทางกลที่ครอบคลุมดี ความแข็งแรงและความยืดหยุ่นที่เข้ากันได้ดี เหมาะสำหรับชิ้นส่วนเปลือกของยานอวกาศ 3C อิเล็กทรอนิกส์ และผลิตภัณฑ์อื่น ๆ ที่มีความต้องการความแข็งแรงปานกลาง |

|

LAZ933 |

1.53 |

50-80 |

190-230 |

145-190 |

10-20 |

43 |

0.33 |

เกี่ยวกับ50-80 |

≤100 ℃ |

คุณสมบัติทางกลที่ครอบคลุมดี เหมาะสำหรับชิ้นส่วนเปลือกของยานอวกาศ 3C อิเล็กทรอนิกส์ และผลิตภัณฑ์อื่น ๆ ที่มีความต้องการความแข็งแรงปานกลาง |

|

LA141 |

1.35 |

40-70 |

110-140 |

90-120 |

10-40 |

43 |

0.33 |

เกี่ยวกับ50-80 |

≤80 ℃ |

ความหนาแน่นต่ำและความเหนียวที่ดี เหมาะสำหรับส่วนประกอบโครงสร้างของยานอวกาศ เช่น ดาวเทียมและยานสำรวจห้วงอวกาศ |

|

MA21 |

1.6 |

50-80 |

200-280 |

130-200 |

6-25 |

45 |

0.33 |

เกี่ยวกับ50-80 |

≤120 ℃ |

มีความแข็งแรงสูง ทนต่อการกัดกร่อนได้ดี เหมาะสำหรับส่วนประกอบที่มีความแข็งแรงปานกลางในด้านการบินและอวกาศ สามารถใช้แทน ME20, AZ40 และผลิตภัณฑ์อื่นๆ ได้ |

|

MA18 |

1.48 |

45-65 |

150-220 |

110-140 |

15-40 |

43 |

0.33 |

เกี่ยวกับ50-80 |

≤80 ℃ |

ความหนาแน่นต่ำ ความแข็งแรงปานกลาง รูปร่างดี ทนต่อการกัดกร่อนได้ดี เหมาะสำหรับชิ้นส่วนเปลือกของยานอวกาศและผลิตภัณฑ์อื่น ๆ |

แมกนีเซียม-ลิเธียมอัลลอยน้ำหนักเบาพิเศษ

ลักษณะของโลหะผสมแมกนีเซียม-ลิเธียม

- เบาเป็นพิเศษ: วัสดุโครงสร้างโลหะที่เบาที่สุดในโลก ด้วยความหนาแน่น 1.35-1.65g/cm3 เบากว่าอลูมิเนียมอัลลอยด์ 1/2 และเบากว่าโลหะผสมแมกนีเซียม 1/3

- ความแข็งแกร่งที่ดีเยี่ยม: ความแข็งแกร่งเป็น 22 เท่าของเหล็กกล้า น้ำหนักของแมกนีเซียมและลิเธียมที่จำเป็นสำหรับความแข็งแกร่งเท่ากันคือ 1 ใน 3 ของน้ำหนักเหล็ก

- ความเป็นพลาสติกยิ่งยวด: การยืดตัวด้วยแรงดึงที่อุณหภูมิสูงของแมกนีเซียม-ลิเธียมสามารถเข้าถึงได้ถึง 758% และชิ้นส่วนผนังบางที่มีขนาดที่แม่นยำ รูปทรงที่ซับซ้อน และโครงสร้างที่สม่ำเสมอและเกรนละเอียดสามารถทำได้โดยการขึ้นรูปซุปเปอร์พลาสติก

- การนำไฟฟ้าและความร้อนที่ดี: การนำความร้อนประมาณ 300 ~ 400 เท่าของพลาสติก, 30 ~ 50 เท่าของวัสดุคอมโพสิตคาร์บอนไฟเบอร์ และการนำไฟฟ้าประมาณ 1016 เท่าของพลาสติก และ 104 เท่าของคอมโพสิตคาร์บอนไฟเบอร์ วัสดุ.

- ประสิทธิภาพการดูดซับแรงกระแทกที่ดีเยี่ยม: มีค่าสัมประสิทธิ์การเสียดสีภายในขนาดใหญ่ ใช้พลังงานภายในโลหะ ปรับปรุงความเสถียรของอุปกรณ์ได้อย่างมีประสิทธิภาพ และเหมาะสำหรับการผลิตอุปกรณ์ที่ต้องการการดูดซับแรงกระแทก เช่น ชิ้นส่วนดูดซับแรงกระแทกสำหรับอากาศยาน เกราะถัง

|

วัสดุ |

ไททาเนียมอัลลอยด์α-Ti |

อลูมิเนียมอัลลอยด์ 5052-O |

magnesium alloy AZ31-H |

plasticPC/ABS |

carbon fiber composite material |

Magnesium Lithium Alloy LZ91 |

|

Internal friction coefficient |

0.002 |

0.002 |

0.004 |

~ 0.01 |

~ 0.03 |

~ 0.01-0.05 |

|

Specific damping coefficient(10-4) |

4.6 |

7.5 |

23 |

82 |

170 |

68-340 |

Internal friction temperature spectrum of as-rolled LZ91 heated at 200 degrees

Internal friction temperature spectrum of as-rolled LA91 at 300°C heating

- Excellent electromagnetic shielding performance: magnesium-lithium alloy has a good shielding effect on electromagnetic waves in different bands, and is suitable for making gyroscope shells, shielding shelters, anti-interference control cabinets, etc., to improve the safety of equipment, accuracy.

|

|

Measurement frequency |

Magnesium Lithium Alloy LZ91 |

Magnesium Lithium Alloy LZA911 |

AZ31 |

PC/ABS |

Carbon fiber composite material |

|

EMI value compare |

1.8GHz |

-66 dB |

-59 dB |

-29 dB |

无 |

-19 dB |

|

2.45GHz |

-79 dB |

-77 dB |

-52 dB |

-27 dB |

7、Good welding performance: Magnesium-lithium is easy to be welded with the bulk alloy and other magnesium alloys, and can be welded by laser welding, friction stir welding, TIG welding, electron beam welding and brazing.

8、Excellent machinability and cold forming ability: Magnesium-lithium has excellent machinability, good surface quality, low cutting force and low energy consumption. Excellent cold workability, the total cold rolling rate can reach 90%, and it can be stamped at room temperature。

Grades, properties and application characteristics of magnesium-lithium alloys

Magnesium-lithium alloy grade and composition

|

Grade |

Li |

Al |

Zn |

Ce |

Si |

Cu |

Fe |

Ni |

Mn |

|

LZ91 |

8.5-9.5 |

- |

0.5-1.5 |

- |

≤0.05 |

≤0.05 |

≤0.01 |

≤0.005 |

≤0.05 |

|

LAZ931 |

8.0-10.0 |

2.5-3.8 |

0.5-1.5 |

- |

≤0.05 |

≤0.05 |

≤0.01 |

≤0.005 |

≤0.05 |

|

LAZ933 |

8.5-10.3 |

2.5-3.5 |

2.5-3.5 |

- |

≤0.05 |

≤0.05 |

≤0.01 |

≤0.005 |

≤0.05 |

|

LA141 |

13.0-15.0 |

0.75-1.5 |

- |

- |

≤0.1 |

≤0.1 |

≤0.1 |

≤0.005 |

≤0.15 |

|

MA18 |

10-11.5 |

0.5-1.0 |

2.0-2.5 |

0.2-0.4 |

0.1-0.4 |

- |

- |

- |

0.1-0.4 |

|

MA21 |

7.0-10.0 |

4.0-6.0 |

0.2-2.0 |

- |

0.1-0.4 |

- |

- |

- |

0.1-0.5 |

Magnesium-lithium alloy properties (forgings, rolled sheets)

|

Grade |

Density g/cm3 |

Mechanical properties |

Operating temperature |

|||

|

hardness HV |

tensile strength MPa |

Yield Strength MPa |

Elongation at break % |

|||

|

LZ91 |

1.48 |

40-75 |

140-180 |

110-130 |

35-60 |

100 ℃以下 |

|

LAZ931 |

1.51 |

50-75 |

170-220 |

140-180 |

20-28 |

100 ℃以下 |

|

LAZ933 |

1.53 |

50-80 |

180-230 |

145-190 |

16-22 |

100 ℃以下 |

|

LA141 |

1.35 |

40-70 |

110-140 |

90-120 |

10-40 |

80 ℃以下 |

|

MA18 |

1.48 |

45-65 |

150-220 |

100-180 |

15-40 |

80 ℃以下 |

|

MA21 |

1.60 |

50-80 |

200-280 |

130-250 |

6-25 |

120 ℃以下 |

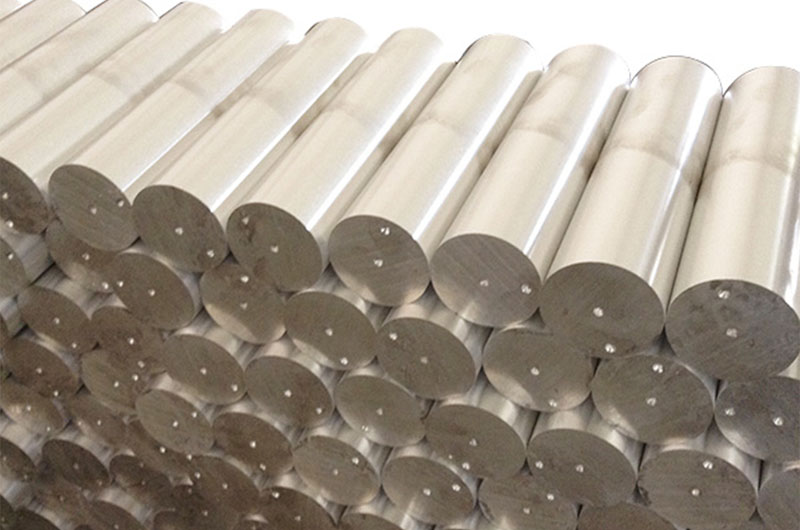

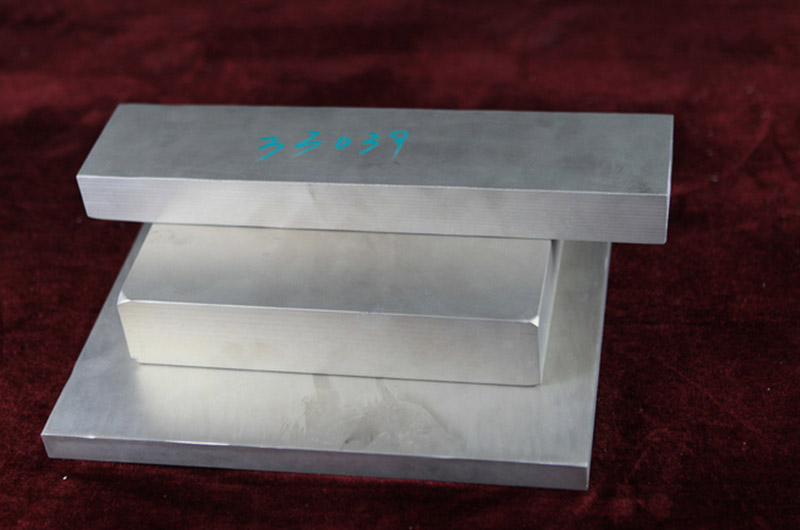

Executive standard: magnesium-lithium alloy ingot Q/ZYYCLS1122—2020

Magnesium-lithium alloy strip Q/ZYYCLS1123—2020

Magnesium-lithium alloy hot extrusion rod Q/ZYYCLS1124—2020

Magnesium-lithium alloy forgings Q/ZYYCLS1125—2019

Application characteristics of magnesium-lithium alloy materials

|

Grade |

Material variety |

Material characteristics and typical uses |

|

LZ91 |

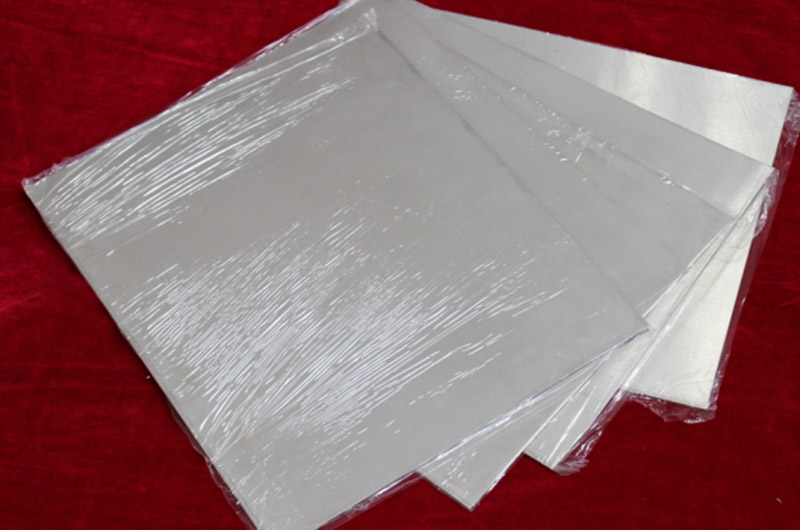

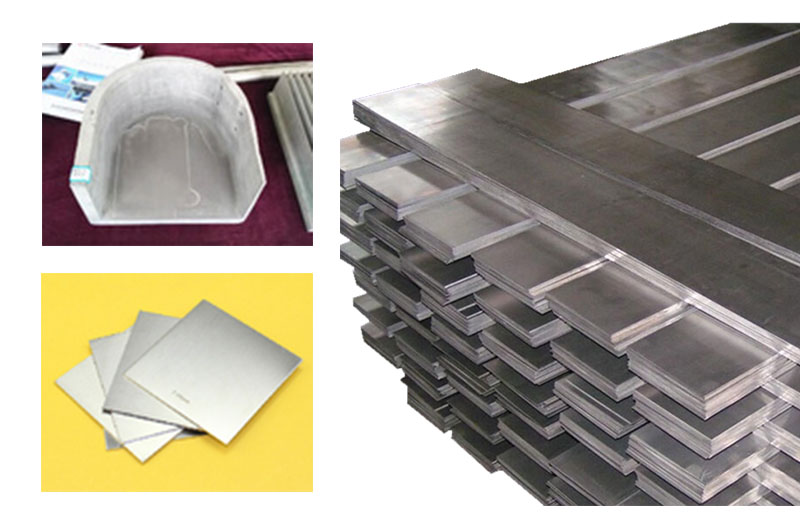

Plates, foils, bars, forgings |

LZ91, LAZ931, LAZ933, LA141 are typical commercial magnesium-lithium alloys, with the same density as plastics, much higher rigidity and toughness than plastics, and excellent shock absorption, damping and plasticity, and can be used in sound film foils. One of the most effective materials for weight reduction in aerospace metal materials. It can be applied to secondary load-bearing parts and various boxes and shells, such as electronic chassis shells, optical instrument structural parts, skins, instrument panels, rivets for satellites, honeycomb panels, heat pipes, notebook shells, mobile phone shells, aiming devices and shell parts.

MA21 and MA18 are the two most practical magnesium-lithium alloys, which have high stability in mechanical properties, corrosion and manufacturability, and can be processed into various forms of deformed workpieces. It can be applied to low-strength welding materials and manufacturing parts that require high specific stiffness and high damping, such as frames, brackets, shells of electronic instruments, waveguides, rocket hatches, etc. |

|

LAZ931 |

||

|

LAZ933 |

||

|

LA141 |

||

|

MA18 |

Sheets, forgings, extrusions, profiles |

|

|

MA21 |

Preparation process of magnesium-lithium alloy

Application areas

In the aerospace field, we will spare no expense to reduce weight. In the military field, in order to meet the tactical needs of long-range delivery, rapid deployment, and maneuvering operations in the future, weapons and equipment are constantly developing towards light weight, and mobile phones, notebooks and other products in the 3C field are becoming lighter and thinner. Development, the use of magnesium-lithium alloys to replace aluminum alloys can achieve a weight reduction effect of 20% to 30%, and immediate results.

The rapid development of the aerospace industry is a symbol of national scientific and technological progress, and has strategic significance in national security. The aerospace industry has very strict requirements on related equipment from design, material, processing, assembly to automation control, etc., especially Strict performance requirements are placed on the material.

Magnesium alloy materials are widely used in aerospace equipment due to their light weight, which can greatly reduce the weight of aircraft. Under the same weight reduction, the fuel cost of fighter jets is 10 times that of commercial aircraft, while commercial aircraft save fuel cost approx.

100 times that of a car. The reduction in the mass of the aircraft can also improve the maneuverability of the aircraft and increase the combat effectiveness of the fighter.

When missiles, launch vehicles and aircraft are in flight, due to engine operation and aerodynamic noise, it will cause severe broadband random vibration and noise environment, and will also stimulate numerous resonance peaks in the structure and electronic control instrument system, resulting in fatigue failure of the structure. and dynamic instability leading to failure. Statistics show that about one-third of the ground and flight test failures of rockets are related to vibration, and the excellent shock absorption performance of magnesium-lithium alloys can meet the relevant shock absorption requirements.

Military field: With the advancement of science and technology, military weapons and equipment are in urgent need of weight reduction. If the weight of fighter jets is reduced by 15%, the rolling distance of the aircraft can be shortened by 15%, the range can be increased by 20%, and the payload can be increased by 30%, especially in wearable equipment. , the need for weight loss is more urgent. Magnesium alloys have been used in this field for nearly 100 years as a lightweight structural material. Replacing aluminum alloys and titanium alloys with magnesium-lithium alloys can achieve a weight reduction effect of 20% to 40%.

3C field: Electronic products such as computers and communication equipment have developed rapidly in recent years. People have higher and higher requirements for the portability of electronic products. The advantages of magnesium-lithium alloys in all aspects are fully suitable for the requirements of high-end electronic products.

Due to the good cold working properties of magnesium-lithium alloys, room temperature stamping can be achieved. In addition, magnesium-lithium alloys also have excellent electromagnetic shielding properties. The magnesium-lithium alloys are used to prepare notebook LCD screen frames, back shells, keyboard frames and other components. While reducing weight, enhancing heat dissipation, and increasing impact resistance, it can also reduce electromagnetic interference, making the transmitted data more real and accurate. A domestic notebook company uses the magnesium-lithium alloy produced by our company to produce an ultrabook with a 15.6-inch display that weighs only 990 grams. Magnesium-lithium alloy has a high specific damping coefficient, and its specific stiffness and specific strength are better than other metals. As an audio diaphragm, it can reduce the power of the equipment, improve the stability of the equipment, and achieve high-fidelity transmission of sound quality.

Typical products and application cases of magnesium-lithium alloys

Magnesium-lithium alloy chassis shell

As the lightest metal structural material, magnesium-lithium alloy has the obvious advantages of light weight and high specific strength, and is widely used in the fields of national defense, military industry, aerospace and other fields. The weight reduction of aircraft means that the fuel consumption of the aircraft is low and the cost is low. The preparation of electronic chassis in fighter planes and UAVs can quickly achieve structural weight reduction. There are also a large number of portable equipment in the military industry that urgently need to lose weight.

More than 300 structural components in the portable radar are replaced with magnesium-lithium alloys, which reduces the structural weight of the radar from 60kg to 35kg, reducing the burden of carrying personnel.

Magnesium-lithium alloy individual soldier equipment

In order to meet the tactical needs of long-range delivery, rapid deployment, and maneuvering operations in future operations, military weapons and equipment are constantly developing towards lightweight, especially in terms of individual wearable equipment, which are mainly used for reconnaissance, stealing, blasting, communication, intelligence. , special tasks, etc., the need for weight loss is more urgent. Replacing magnesium alloys, aluminum alloys, and titanium alloys with magnesium-lithium alloys can reduce weight by 20% to 50%. Magnesium-lithium alloys can be used in individual soldier equipment: weapon sighting devices, telescopes, helmet covers and suspension devices, video Enhanced image intensifiers, flat-panel displays, miniature cameras, audio-visual support devices, exoskeletons for individual soldiers, filling plates for bulletproof vests, etc.

Material: magnesium lithium alloy

Density: 1.35-1 .6g/cm3

Processing: CNC, EDM, wire cutting, etc.

Surface: Micro-arc oxidation electrophoresis composite treatment, passed the national military standard three-proof test

Features: light weight, shock absorption, electromagnetic shielding, can replace magnesium alloy, aluminum alloy, carbon fiber, etc.

Body armor inner lining

Tested by the China Military Equipment Quality Inspection Center, magnesium-lithium alloys have excellent anti-ballistic properties, not only the excellent shock absorption properties of magnesium alloys, but also the toughness and energy-absorbing effects of aluminum alloy armors. Weight reduction can increase mobility and flexibility. Shock absorption can reduce the vibration caused by bullet impact, effectively protect soldiers, and can also be used for helicopters and tank armor that need weight reduction.

Individual Soldier Carrying Station Shell

The shell of a soldier carrying station of a certain Ordnance Group is made of magnesium-lithium alloy after processing. Head Mounted Display System Components night vision device.The night vision device designed by a certain AVIC Group is made of magnesium-lithium alloy, and its structure is about 46% lighter than that of aluminum alloy.

Magnesium-lithium alloy notebook products

With the continuous improvement of living standards, people have higher and higher requirements for the portability of electronic products. As the most commonly used electronic products outside mobile phones, notebook computers are rapidly developing in the direction of thinness and lightness. The advantages of magnesium-lithium alloys in all aspects are fully suitable for high-end Electronic product requirements.

The notebook made of magnesium-lithium alloy passed: √Vibration adaptability test √Shock test √Crash test √Free drop test √Boil test

Parts Material: magnesium-lithium alloy Density: 1.48-1.6g/cm3

Processing: stamping, precision forging, CNC

Features: light weight, small deformation, can be stamped at room temperature, the total weight of the notebook is less than 1kg

wearable products

In recent years, smart wearable devices have been widely recognized by the market as the next hot spot in the smart terminal industry. The mainstream product forms of wearable devices include watches, shoes, Glass and other mainstream product forms.

The quality, performance, size, material, etc. of the equipment determine the function and user experience of the product. As the lightest metal structural material, magnesium-lithium alloy can reduce the burden of long-term wearing and improve the user experience compared with aluminum alloy.

AR glasses frame Material: magnesium-lithium alloy QY-1 Density: 1.55g/cm3 Forming process: Semi-solid Features: High strength, light weight, small deformation, complete filling, no defects

VR glasses bracket Material: magnesium-lithium alloy LAZ931 Density: 1.52g/cm3 Molding process: Die casting Features: High strength, light weight, small deformation

Magnesium-lithium alloy welding

Magnesium-lithium alloys have excellent weldability, and the welding process is not much different from that of magnesium alloys. It is easy to weld with bulk alloys and other magnesium alloys. TIG welding, electron beam welding, laser welding, friction stir welding and brazing and other techniques for welding.

The welding seam obtained by laser welding is smooth and clean. It can be seen from the microstructure photos that the welding seam area is mainly composed of fine columnar crystals. After testing, the welding seam strength can reach 85% of the matrix.

LZ91 alloy friction stir welding, from a macro point of view, the surface of the welded joint area is relatively flat, slightly lower than the plate plane, showing the characteristics of "onion ring", and the shape is good. The cross-section of the welded joint area was observed at low magnification by optical microscope and scanning electron microscope, and no common defects such as tunnels, pores, and cracks were found in welding. Moreover, with the increase of heat input, the tensile strength and yield strength of the welding center area showed the same value. Uptrend, elongation decreased slightly.

Typical performance parameters of magnesium-lithium alloys

Magnesium-lithium alloy LZ91 parameter table

Magnesium-Lithium Alloy LZ91 Chemical Composition

|

Li |

Zn |

Mn |

Si |

Fe |

Cu |

Ni |

Mg |

|

8.5-9.5 |

0.5-1.5 |

≤0.05 |

≤0.05 |

≤0.01 |

≤0.05 |

≤0.005 |

Bal. |

Physical properties of magnesium-lithium alloy LZ91

|

density(g/cm3) |

1.48 |

|

solidus temperature(℃) |

570 |

|

liquidus temperature(℃) |

582 |

|

Elastic Modulus(GPa) |

43 |

|

Poisson's ratio |

0.33 |

|

Thermal Conductivity(W/mK)(25℃) |

50-80 |

|

Thermal expansion coefficient(10-6/K)(25℃) |

28-32 |

|

Internal friction coefficient |

0.01-0.05 |

|

Specific damping coefficient(10-4) |

68-340 |

Magnesium-Lithium Alloy LZ91 Mechanical Properties Standard

|

Temper |

Size/mm |

tensile strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

|

forging |

O |

≤100 |

≥110 |

≥90 |

≥25 |

|

H112 |

≥120 |

≥95 |

≥25 |

||

|

Extruded state |

H112 |

≤20 |

≥145 |

≥100 |

≥30 |

|

>20~50 |

≥135 |

≥95 |

≥25 |

||

|

>50~190 |

≥130 |

≥90 |

≥25 |

||

|

rolled sheet |

O |

0.40~3.00 |

≥130 |

≥95 |

≥25 |

|

>3.00~12.50 |

≥125 |

≥95 |

≥25 |

||

|

>12.50~20.00 |

≥120 |

≥90 |

≥20 |

||

|

H112 |

2.00~12.50 |

≥135 |

≥100 |

≥25 |

|

|

>12.50~70.00 |

≥130 |

≥95 |

≥20 |

||

Measured values of mechanical properties of magnesium-lithium alloy LZ91

|

Temper |

Size/mm |

tensile strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

|

forging |

O |

76mm |

117 |

96 |

37.5 |

|

H112 |

133 |

103 |

32.5 |

||

|

Extruded state |

H112 |

φ16 |

157 |

109 |

47.5 |

|

φ22 |

151 |

101 |

38.0 |

||

|

φ190 |

140 |

96 |

35.5 |

||

|

rolled sheet |

O |

2.5 |

141 |

113 |

48.0 |

|

8 |

139 |

107 |

44.5 |

||

|

15 |

134 |

96 |

42.0 |

||

|

H112 |

3 |

142 |

114 |

43.5 |

|

|

45 |

136 |

106 |

38.0 |

||

Magnesium-Lithium Alloy LAZ931 Parameter Table

Magnesium-Lithium Alloy LAZ931 Chemical Composition

|

Li |

Al |

Zn |

Mn |

Si |

Fe |

Cu |

Ni |

Mg |

|

8.0-10.0 |

2.5-3.8 |

0.5-1.5 |

≤0.05 |

≤0.05 |

≤0.01 |

≤0.05 |

≤0.005 |

Bal. |

Magnesium-Lithium Alloy LAZ931 Physical Properties

|

density(g/cm3) |

1.51 |

|

solidus temperature(℃) |

560 |

|

liquidus temperature(℃) |

580 |

|

Elastic Modulus(GPa) |

43 |

|

Poisson's ratio |

0.33 |

|

Thermal Conductivity(W/mK)(25℃) |

50-80 |

|

Thermal expansion coefficient(10-6/K)(25℃) |

28-32 |

Magnesium-Lithium Alloy LAZ931 Mechanical Properties Standard

|

Temper |

Size/mm |

tensile strength/MPa |

Yield Strength/MPa |

Elongation% |

|

|

forging |

O |

≤100 |

≥160 |

≥130 |

≥12 |

|

H112 |

≥175 |

≥135 |

≥10 |

||

|

Extruded state |

H112 |

≤20 |

≥185 |

≥155 |

≥20 |

|

>20~50 |

≥175 |

≥145 |

≥15 |

||

|

>50~190 |

≥165 |

≥135 |

≥15 |

||

|

rolled sheet |

O |

0.40~3.00 |

≥170 |

≥140 |

≥12 |

|

>3.00~12.50 |

≥165 |

≥130 |

≥12 |

||

|

>12.50~20.00 |

≥160 |

≥130 |

≥12 |

||

|

H112 |

2.00~12.50 |

≥185 |

≥155 |

≥12 |

|

|

>12.50~32.00 |

≥175 |

≥145 |

≥12 |

||

|

>32.00~70.00 |

≥165 |

≥135 |

≥12 |

||

Measured values of mechanical properties of magnesium-lithium alloy LAZ931

|

Temper |

Size/mm |

tensile strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

|

forging |

O |

90mm |

169 |

137 |

21.5 |

|

H112 |

183 |

144 |

17.5 |

||

|

Extruded state |

H112 |

φ16 |

208 |

167 |

24.0 |

|

φ22 |

199 |

162 |

21.0 |

||

|

φ190 |

181 |

154 |

18.0 |

||

|

rolled sheet |

O |

2.5 |

177 |

140 |

29.5 |

|

6 |

175 |

138 |

28.5 |

||

|

15 |

168 |

134 |

14.50 |

||

|

H112 |

3 |

188 |

158 |

27.0 |

|

|

20 |

183 |

152 |

16.0 |

||

|

50 |

171 |

144 |

14.5 |

||

Magnesium-Lithium Alloy LAZ933 Parameter Table

Magnesium-Lithium Alloy LAZ933 Chemical Composition

|

Li |

Al |

Mn |

Si |

Fe |

Cu |

Ni |

Mg |

|

8.5-10.3 |

2.5-3.5 |

≤0.05 |

≤0.05 |

≤0.01 |

≤0.05 |

≤0.005 |

Bal. |

Magnesium-Lithium Alloy LAZ933 Physical Properties

|

density(g/cm3) |

1.53 |

|

solidus temperature(℃) |

560 |

|

liquidus temperature(℃) |

580 |

|

Elastic Modulus(GPa) |

43 |

|

Poisson's ratio |

0.33 |

|

Thermal Conductivity(W/mK)(25℃) |

50-80 |

|

Thermal expansion coefficient(10-6/K)(25℃) |

25-33 |

Magnesium-Lithium Alloy LAZ933 Mechanical Properties Standard

|

Temper |

Size/mm |

tensile strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

|

forging |

O |

≤100 |

≥175 |

≥140 |

≥10 |

|

H112 |

≥185 |

≥145 |

≥8 |

||

|

Extruded state |

H112 |

≤20 |

≥205 |

≥175 |

≥20 |

|

>20~50 |

≥185 |

≥155 |

≥15 |

||

|

>50~190 |

≥175 |

≥145 |

≥10 |

||

|

rolled sheet |

O 态 |

0.40~3.00 |

≥185 |

≥145 |

≥10 |

|

>3.00~12.50 |

≥175 |

≥140 |

≥10 |

||

|

>12.50~20.00 |

≥170 |

≥135 |

≥10 |

||

|

H112 态 |

2.00~12.50 |

≥195 |

≥160 |

≥10 |

|

|

>12.50~32.00 |

≥185 |

≥155 |

≥10 |

||

|

>32.00~70.00 |

≥175 |

≥145 |

≥10 |

||

Measured values of mechanical properties of magnesium-lithium alloy LAZ933

|

Temper |

Size/mm |

tensile strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

|

forging |

O |

80 |

186 |

148 |

23.5 |

|

H112 |

199 |

152 |

18.5 |

||

|

Extruded state |

H112 |

φ16 |

225 |

191 |

22.0 |

|

φ48 |

219 |

180 |

19.0 |

||

|

φ110 |

196 |

168 |

15.0 |

||

|

rolled sheet |

O |

2.5 |

191 |

151 |

38.5 |

|

10 |

187 |

148 |

35.0 |

||

|

15 |

183 |

144 |

32.0 |

||

|

H112 |

3 |

209 |

166 |

31.5 |

|

|

15 |

189 |

159 |

27.0 |

||

|

40 |

184 |

156 |

22.5 |

||

Magnesium-Lithium Alloy LA141 Parameter Table

Magnesium-Lithium Alloy LA141 Chemical Composition

|

Li |

Al |

Mn |

Si |

Fe |

Cu |

Ni |

Mg |

|

13.0-15.0 |

0.75-1.5 |

≤0.15 |

≤0.1 |

≤0.1 |

≤0.1 |

≤0.005 |

Bal. |

Magnesium-Lithium Alloy LA141 Physical Properties

|

density(g/cm3) |

1.35 |

|

solidus temperature(℃) |

560 |

|

liquidus temperature(℃) |

580 |

|

Elastic Modulus(GPa) |

43 |

|

Poisson's ratio |

0.33 |

|

Thermal Conductivity(W/mK)(25℃) |

50-80 |

|

Thermal expansion coefficient(10-6/K)(25℃) |

27-32 |

Magnesium-Lithium Alloy LA141 Mechanical Properties Standard

|

Temper |

Size/mm |

tensile strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

|

forging |

O |

≤100 |

≥125 |

≥90 |

≥25 |

|

H112 |

≥130 |

≥95 |

≥20 |

||

|

Extruded state |

H112 |

≤20 |

≥120 |

≥90 |

≥20 |

|

>20~50 |

≥110 |

≥85 |

≥20 |

||

|

>50~190 |

≥100 |

≥80 |

≥20 |

||

|

rolled sheet |

O |

0.40~3.00 |

≥130 |

≥100 |

≥20 |

|

>3.00~12.50 |

≥125 |

≥95 |

≥20 |

||

|

>12.50~20.00 |

≥120 |

≥90 |

≥20 |

||

|

H112 |

2.00~12.50 |

≥140 |

≥100 |

≥20 |

|

|

>12.50~70.00 |

≥130 |

≥95 |

≥20 |

||

Measured values of mechanical properties of magnesium-lithium alloy LA141

|

Temper |

Size/mm |

tensile strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

|

forging |

O |

85 |

141 |

94 |

28.5 |

|

H112 |

144 |

105 |

24.0 |

||

|

Extruded state |

H112 |

φ8 |

143 |

108 |

33.0 |

|

φ22 |

138 |

104 |

29.0 |

||

|

φ70 |

129 |

98 |

27.5 |

||

|

แผ่นรีด |

อู๋ |

2 |

137 |

112 |

33.5 |

|

10 |

133 |

101 |

31.0 |

||

|

15 |

131 |

94 |

28.5 |

||

|

H112 |

10 |

149 |

114 |

27.0 |

|

|

50 |

143 |

99 |

25.5 |

||